FabriCar repair center:

CO₂-neutral into the future with high-tech and geothermal energy

FabriCar in Bad Aibling is the first body and paint store to consistently rely on renewable energy for heat and electricity, operate CO₂-neutrally and use geothermal energy in addition to photovoltaics. This was made possible by a modern extension at the same site, which gave the existing paint shop a new, modern home.

Christian Kucz, owner of FabriCar, used the expansion to consistently implement a future-oriented sustainability strategy for his entire business. The requirements were high: no more fossil fuels, heat and electricity from in-house production – not only for the new paint shop, but also for the existing building – combined with the latest energy-saving paint shop technology.

The contract to implement FabriCar’s wishes and requirements was awarded to the German system manufacturer Sehon innovative paint systems from near Stuttgart. Sehon and its system partner Premiotherm are regarded as absolute leaders when it comes to sustainable, environmentally friendly high-tech paint shops and heat supply systems for paint stores. “What is unique in the industry so far,” says Tiemo Sehon, “is that Fabricar is using geothermal energy for the first time, i.e. geothermal energy for the building’s energy supply, for hot water, for heating and for operating the painting systems and dryers.”

FabriCar repair center in Bad Aibling.

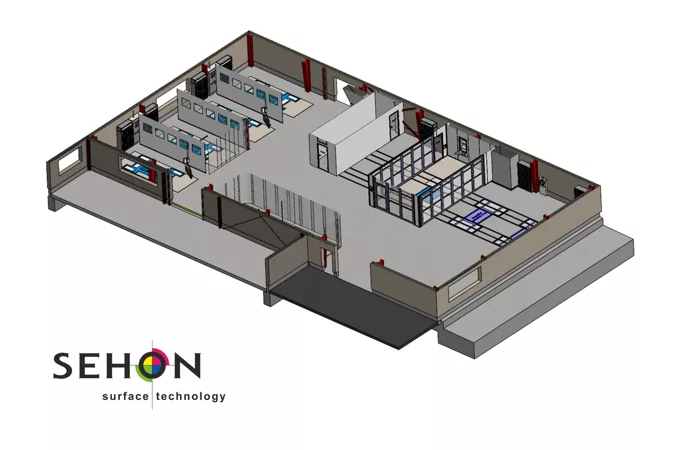

Process-oriented design and equipment of the new paint shop.

New energy center with heat pumps, storage tank and control system.

High-end SE-PROFESSIONAL FUTURA combination spray booth from SEHON.

Geothermal energy refers to the thermal energy stored in the earth’s crust and its technical use. Geothermal energy can be used for heating, cooling and power generation. At FabriCar, ambient heat from the ground, namely from the groundwater, is used to generate energy via heat pumps. For this purpose, a well system consisting of two extraction wells and two return wells was installed in the groundwater close to the surface. Heat is extracted from the groundwater through the extraction wells, while the cooled water is returned to the groundwater via the return wells.

In Germany, every borehole up to a depth of 100 meters must be approved by the lower water authority, which are usually the water management offices of the districts and independent cities. Like all renewable forms of energy, the use of geothermal energy is subsidized by the state. In order to receive maximum funding, it is necessary to carefully check which funding programs can be used at state and regional level.

FabriCar’s own photovoltaic system and geothermal energy are the main energy suppliers. The trick is to adapt the energy generated in this way and its consumption to the operational requirements. This is because paint stores are subject to major fluctuations in energy consumption, both in day-to-day business and seasonally. The Bad Aiblingen-based company uses an intelligent energy management system that automatically controls all processes and ensures perfect interaction and monitoring of energy production, energy storage and energy consumption. Surplus energy is fed into the utility’s general power grid and green electricity from renewable sources is used when required. The company has an excellent environmental footprint, as it produces more energy than it consumes all year round. FabriCar does not use any fossil fuels at all, meaning that its energy supply is CO₂-neutral.

Paint mixing room, masking, painting and drying, finish.

Cross-feed rail system between the individual process steps.

Universal preparation stations and multifunctional workstations.

Finish workstations at FabriCar. Floor-level lifting platforms.

The paint store works with systems and workstations from Sehon, which are fully integrated into the heat and energy concept. Especially with the symbiosis of high-tech and green technology, it was important for FabriCar to obtain everything from a single source. This is the only way to ensure smooth interaction between energy and painting technology. The SE-Professional Futura combi-painting booth with integrated drying function is at the heart of the painting process. This premium booth is one of the world’s energy-saving champions and requires over 80 % less energy than comparable spray booths with little or no energy-saving technology. For a sustainable paint store, it is important that the traditionally large energy consumers such as the booth and dryer use minimal energy from the outset. The new combi spray booth has a year-round heat recovery system with a rotary heat exchanger and a recovery rate of around 70 %.

Sehon also supplied 4 universal workstations, 2 parts workstations, 1 central supply terminal, 1 multifunctional workstation with rail-guided IR/UV drying, 1 masking workstation, 7 Powerlifter lifting platforms with floor-level installation, 1 paint supply room and 1 cross-push rail system between masking, painting/drying and finishing.

“FabriCar’s new paint center with photovoltaics and geothermal energy is a milestone for us in the design of modern and sustainable paint stores,” summarizes Tiemo Sehon, “we are proud to be able to make an important contribution to the success of the new building with our know-how and technology. We would like to thank Christian Kucz and his team for their trust and support.”

FabriCar

Christian Kucz

Gewerbepark Markfeld 4a

83043 Bad Aibling

Phone: 0 80 61 – 93 93 10

Fax: 0 80 61 – 93 93 129

E-mail: reparatur@fabricar.de

Author: Michael Teschke, Photos: FabriCar, 3D graphics: SEHON.